The advent of software-defined vehicles (SDVs) is expected to significantly

increase the volume of generated vehicle data, necessitating smarter data

forwarding from the vehicle. Data management solutions, like the one

offered by aicas, can assist OEMs and fleet operators in managing this data

effectively.

Enhancing Vehicle Telemetry and Signal Data Collection

Vehicle telemetry and signal data collection are crucial for regulatory

compliance. Beyond the vehicle data mandated and used during servicing,

additional signal values or data points can be recorded to enhance user

experience and to support development of new vehicle features of future

models. AI algorithms can also be employed to identify patterns or trends,

facilitating further improvements.

However, current data management approaches have limitations:

- Lack of a common taxonomy: There is no standardized naming

convention of signals

- Inconsistent sampling rates, units and signal representation:

These vary not only between OEMs but also across different platforms

- Proprietary solutions: Existing solutions are often proprietary

and not universally applicable

- High transmission costs: Despite the massive bandwidths offered by

LTE, 5G and other technologies, the associated cost of transmitting all

available signals would be enormous. Therefore, filtering and dynamic

selection of data are necessary

A collaborative solution involving OEMs, fleet operators and insurance

companies is required to address these challenges.

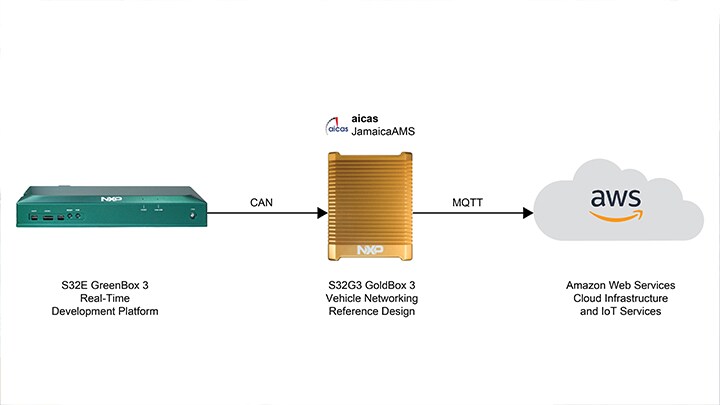

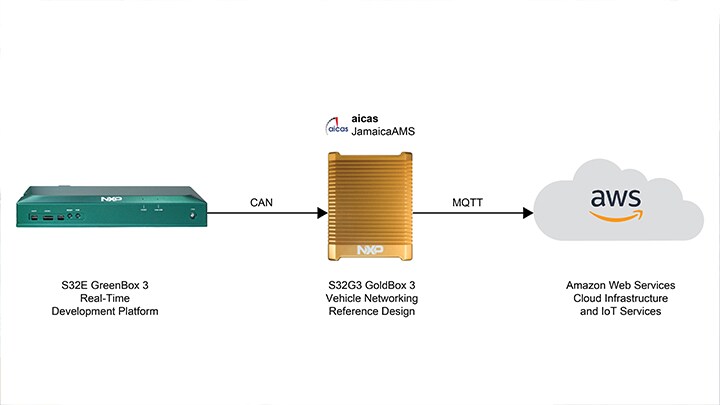

Vehicle Signal Specification (VSS) data management solution (aicas GmbH, 2024).

Vehicle Signal Specification (VSS) data management solution (aicas GmbH, 2024).

Aicas’s proposed solution incorporates the following components to address

some of the issues mentioned above:

- Common Vehicle Domain Taxonomy: Based on the open standard COVESA Vehicle Signal Specification (VSS)

- VSS is a catalog of signals related to vehicles

- VSS is a syntax for defining and organizing vehicle signals in a structured manner

For more details, see COVESA and GitHub pages.

- Normalization of signal data: The necessary (meta) information to normalize the signal data is part of the VSS signal specification for each vehicle model

- Flexible data selection: Scenario-based selection of data to be sent to the data center is available

- Graphical editor: To simplify the development of this collection scheme, a graphical editor that shows the data collection management of the target system as a flow is utilized

- Signal synthesis and mapping: The flexibility of this approach also allows us to synthesize signals from existing raw data or map additional, non-standard signals into the collection scheme

Drive the future of automotive innovation with NXP’s cutting-edge development platforms. Learn more about the capabilities of GreenBox 3 and GoldBox 3 platforms.

Details of the Solution

The software agent is implemented as a set of services running inside the

JamaicaAMS application management runtime system, a framework for

component-based applications.

With JamaicaAMS, embedded systems can be easily and flexibly updated and

reconfigured, remotely and at any time during runtime. The ability to reuse

components on various supported systems provides full scalability for

applications across fleets of vehicles. Within the JamaicaAMS component

system, the AWS FleetWise compatible data collection system is implemented

as a set of individual and independent software modules which communicate

asynchronously with each other via an internal message bus.

The three major components of this solution are:

- Signal conversion and normalization from the CAN bus

- Signal selection

- Signal transfer to the data center or cloud

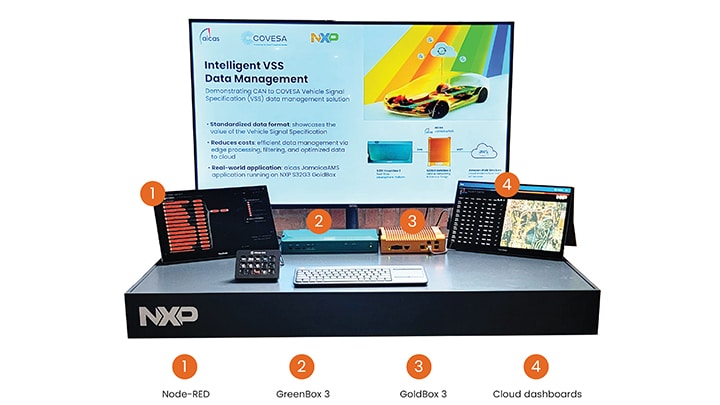

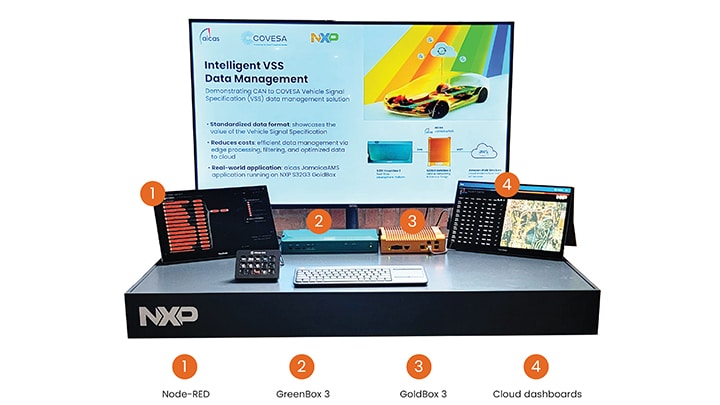

System Demonstration on NXP Hardware

The system that allows real-time vehicle data access and management can be

seen in the figure below.

The demonstration system with NXP hardware and aicas software showcasing

VSS data management (NXP Semiconductors, 2024).

The demonstration system with NXP hardware and aicas software showcasing

VSS data management (NXP Semiconductors, 2024).

It comprises four main parts: NXP GreenBox 3 real-time development platform

(number 2 in figure), GoldBox 3 (3), Node-RED (1) and cloud dashboards (4).

The user can configure data selection flows related to vehicle dynamics,

battery management and energy management within Node-RED (screen marked 1)

and investigate the collected data on real-time cloud dashboards (4). The

low-code environment offered by Node-RED allows dynamic remote

reconfiguration on-the-fly for easy prototyping. A real vehicle system is

illustrated by the GreenBox 3 (CAN data source; number 1 in figure), and

the GoldBox 3 (CAN receiver and data processor; number 3 in figure)

combination from NXP, connected via a physical CAN bus.

Safe and secure S32G3 processors enhance vehicle networking and meet the

demands of next-generation vehicle architectures. Learn more about

S32G3.

With the CAN-to-VSS mapping and signal normalization, the ability of

defining signal collection schemes on these VSS signals, and the capability

to create vehicle models and group these into fleets, the aicas EdgeSuite

solution enables customers to quickly start with data collection and

management solutions without having to build systems from scratch. Their

embedded and cloud dashboards provide sophisticated data management for

fleet operators.

The solution can be deployed on NXP’s automotive processors. The NXP S32G3

vehicle network processor provides high-speed vehicle networking, POSIX

compute with Arm® Cortex®-A53 cores and ASIL D-capable computing using Arm

Cortex-M7 cores in lockstep.

Takeaways

The aicas and NXP collaboration leverages VSS through aicas EdgeSuite for

vehicle and fleet data management using NXP’s automotive processors: the

NXP S32G3 vehicle network processor and the NXP S32E2 real-time processor.

The integration of VSS provides several key benefits:

- Reduction of vehicle data fragmentation

- Easier integration of Tier-1 software and ECUs

- Collaboration with off-vehicle actors (e.g. charging stations)

Aicas EdgeSuite products enable customers to focus on rapid development of

data collection and management solutions without the need to create an

entire framework from scratch.

Discover more about this solution and it’s benefits by exploring our

dedicated

white paper.